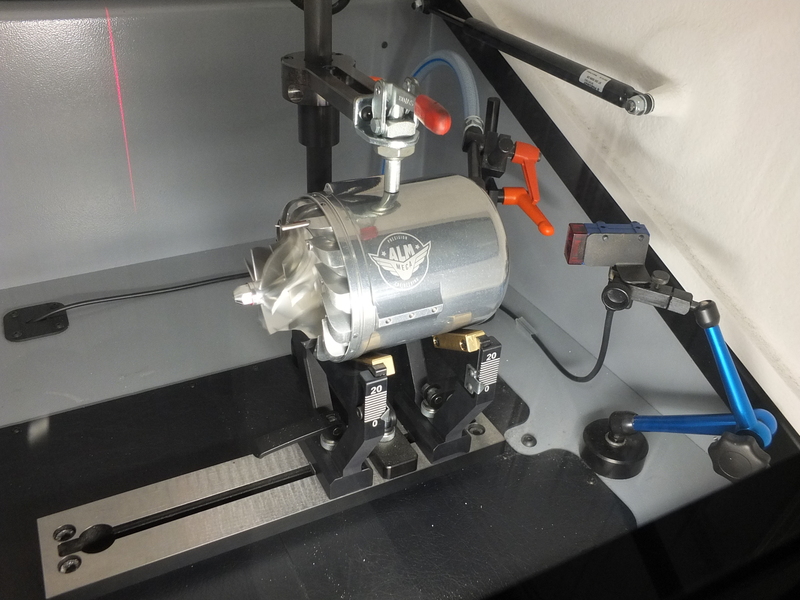

Stop the turbulence! With turbines, unbalance is a ubiquitous phenomenon that is hard to combat over the entire operating range. So, for us, it is a question of finding the best possible balancing of the rotating part, ensuring class G2.5 or better. Our know-how allows us to balance and rebalance all rotating machines used in this field.

Since imbalance generates a linearly increasing centrifugal force, the faster a rotor spins, the more noticeable the imbalance becomes. The main cause of the imbalance, which may be due to a misalignment of the axes or an imbalance of the materials, must therefore be found in order to achieve optimum rotor balance.

We offer dynamic balancing solutions that can eliminate the imbalance and increase machine life. Thus, our solutions fix the maintenance interval on our bearings at 50 hours (under respect of our conditions and recommendations of use). With optimal rotor balancing, we maximise the efficiency of both the machines and our turbines.

For a good rotor balance, do not be heavy with the imbalance!